PRODUCTS

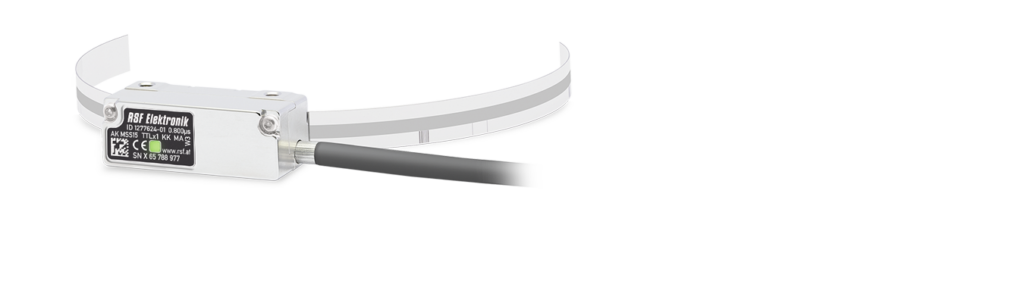

MSS 15

Incremental modular angle measurement in segment version

Home > Products > Modular Angle Encoders > MSS 15

MSS 15 |Overview

Incremental modular angle encoders MSS 15 without integral bearing are used as position and rotator control for electrical drives and in the measurement technology.

- Online signal stabilization

- Display of the signal quality directly at the scanning head via 3-coloured LED function

- Permanent control of the signals over the whole measuring range

- High quality of the signals due to singlefield scanning

Distribution Austria

RSF Elektronik Ges.m.b.H

MSS 15 |Technical data

| Model | AK MSS 15 1Vpp | AK MSS 15 TTLx1u | AK MSS 15 TTLx5 | AK MSS 15 TTLx10 | AK MSS 15 TTLx20 | AK MSS 15 TTLx25 | AK MSS 15 TTLx50 | AK MSS 15 TTLx100 | AK MSS 15 TTLx200 |

| Interface | ∿ 1 Vpp | TTL | TTL | TTL | TTL | TTL | TTL | TTL | TTL |

| Measuring step [°] | Depending on external interpolation | 360°/(LPR × 4) | 360°/(LPR × 20) | 360°/(LPR × 40) | 360°/(LPR × 80) | 360°/(LPR × 100) | 360°/(LPR × 200) | 360°/(LPR × 400) | 360°/(LPR × 800) |

| Integrated interpolation | -- | Times 1 | Times 5 | Times 10 | Times 20 | Times 25 | Times 50 | Times 100 | Times 200 |

| Max. circumferential speed at scanning diameter D [m/s] | 10.00 | 10.00 | 6.40 | 3.20 | 2.40 | 1.92 | 1.92 | 0.96 | 0.96 |

| Max. output frequency | 250 kHz | -- | -- | -- | -- | -- | -- | -- | -- |

| Edge separation amin | -- | 500 ns | 300 ns | 300 ns | 200 ns | 200 ns | 100 ns | 100 ns | 50 ns |

| Further features of the scanning head | |

| Interpolation error | ±(60)" / D |

| Electrical connection | Cable, 0.5 m, 1 m or 3 m with D-sub connector 15-pin (male) |

| Voltage supply | +5 V ±10 % |

| Power consumption | Max. 880 mW (unloaded) |

| Current consumption | Max. 160 mA (unloaded) |

| Vibration | ≤150 m/s² (40 to 2000 Hz) |

| Shock | ≤750 m/s² (8 ms) |

| Permissible temperature | −20 °C to +70 °C (storage), 0 °C to +70 °C (operation) |

| Mass (approx.) | Scanning head: 17g Cable: 25 g/m D-sub connector: 28 g |

| Model | MB MSS 15: Steel tape scale with adhesive tape (SK) |

| Coefficient of expansion | αtherm ≈ 10 x 10–6 K–1 |

| Possible scanning diameter | > 75 mm to ≤ 1000 mm (at larger diameters MS 15 applicable) ≤ 75 mm on request |

| Accuracy of the grating (based on neutral axis) | ±15 µm/m |

| Theoretical lines per revolution (360°) | LPR = 78.5398 × D + 33.1942 (round down result to integer) |

| Reference marks |

|

| Mass (approx.) | 20 g/m |

MSS 15 |Accessories

Mounting aid MH MSx 15

Mounting aid for the scanning head of MSR 15 und MSS 15 (diameter-dependent).

PWT 100 / PWT 101

The PWT 100 / PWT 101 is a testing device for checking the function and adjustment of RSF Elektronik encoders. Thanks to its compact dimensions and robust design, the PWT 100 / PWT 101 is ideal for mobile use. A 4.3-inch touchscreen provides for display and operation. For example, for encoders with EnDat interface you can not only display the position value but also export the online diagnosis, shift datums, and perform further inspection functions.

Available functions

The performance range of the PWT 100 / PWT 101 can be expanded by firmware update. Appropriate firmware files that can be imported to the PWT 100 through a memory card (not included in delivery) will be made available at www.heidenhain.de.

MSS 15 |Downloads

| 3d models | |

|---|---|

| MB_MSS15SK_D100_a100_k0 | 26.70 KB |

| AK_MSx15 | 415.31 KB |

| Mounting Instructions | |

|---|---|

| AK MSR 15, AK MSS 15 | 2186.32 KB |

| MB MSS 15 | 1303.95 KB |

| EC Declaration of conformity | |

|---|---|

| MSS 15- EC declaration of conformity | 538.05 KB |

| Catalogues | |

|---|---|

| MSR 15, MSS 15 | 2249.43 KB |